TRUE CI VERTICAL GIRT SYSTEM

-

Vertical Girt

- VG-8

-

Insulation Strut

- IST-2, IST-4, IST-6

-

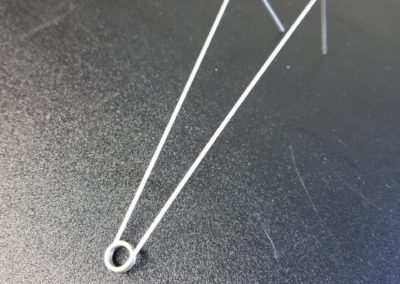

Locking Pins

-

- LP-2

True CI V-Girt is an outboard continuous insulation mounting system defined in ASHRAE Standard 90.1-2013 as: Insulation that is uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings. Additionally, True CI V-Girts are structurally supporting without the use of rigid insulation, making it possible for low density insulation to be used in traditional places of high density. The True CI V-Girt system utilizes a vertically outboard mounted girt with anti-reversing holding pins. The holding pins will allow much larger inward live loads than other outboard systems. The vertical girts can be planed and plumbed without the use of shims or other spacing material. The True CI V-Girt system utilizes the outboard mounting of insulation struts which eliminates standard insulation mounting pins to save time and expense mounting the insulation with minimal weather barrier penetrations.

True CI V-Girt has increased load capacity and excellent thermal transfer reduction over traditional outboard mounting systems. The True CI V-Girt System can be used with any depth high or low-density rigid insulation up to 6″. The insulation struts are attached outboard of the insulation which eliminates needless drilling and needless weather barrier penetrations. Because this system can always be used with low-density insulation versus high-density, the overall cost of the project will be less based on this cost factor alone.

General benefits:

- Can be used with the majority of facade materials.

- Absolute minimal wall penetrations for maximum thermal performance.

- Much easier to calculate and adjust for structural loads of the various facade materials.

- Does not require rigid insulation (or any insulation for that matter) allowing for use of low density insulation with both weight and cost reductions.

- Can be used with any exterior insulation type such as mineral wool and foam boards.

- May include all steps from mounting the insulation all the way through planing, leveling and plumbing of walls in a single pass with potential huge savings of time and labor.

Benefits in comparison to traditional thermal clips:

- Faster installation (how much faster to be determined).

- Only screws are located within the insulation for unsurpassed thermal performance.

- 100% friction fit insulation with no clips located between batts to create potential gaps.

- Only the stud locations need to be marked. No need to measure or mark horizontal locations.

- No need to install thermal clips as an additional step prior to installation of insulation.

- No need to install 2 screws per thermal clip as only one screw will be needed per location. (to be shown/proved in calculations)

- No need to install insulation separately including adding 4-6 insulation holding pins for each batt that contact or penetrate the weather barrier.

- Single screw alignment at stud locations; all additional screws automatically align using our interconnecting girts.

- May be used to plane the wall without the use of additional sub-girts.

Benefits in comparison to other outboard insulation mounting systems:

- Faster installation (how much faster to be determined).

- Does not require rigid insulation to support facade loads allowing for use of low density insulation which has both weight and cost reduction benefits.

- No need to install insulation as a separate step including traditional insulation holding pins that will contact or penetrate the weather barrier.

- Minimal deflection greatly reducing or eliminating potential damage to the insulation which may allow for gaps providing an ingress for thermal, water, moisture and possibly fire transfer(s) to the substrate.

- Minimal and predictable deflection that will not negate facade testing including years later after continuous static and dynamic load application. Additionally the facade system will not sag, oil-can or otherwise deform due to deflection of the mounting system.

- May be used to plane the wall without the use of additional sub-girts.

- Because rigid insulation is not required, less attachment screws and therefore less penetrations through the weather barrier may be possible.

System Information

- True Blue Products True CI V Girt Flyer

- Load Chart

- Structural Test Report (Available on Request)

- Instructional Video

System Drawings

Specifications

INSULATION STITCHES

General benefits:

- A new fast and easy way to hold smaller pieces of insulation to installed insulation that does not contact or penetrate the weather barrier.

- Little or no thermal transfer to the substrate.

- Considerable time savings and it does not require tools.